EPS Production Lines & Shape Molding Systems

Complete Foam Factory Solutions | CIF Machinery for Block, Packaging & Molded EPS

Build an EPS Plant That Actually Runs — Not Just Looks Good on Paper

At SMACHCO, we build real EPS factories for real production environments — not showroom rigs for EPS Production Line.

Whether you’re producing insulation panels, fish boxes, protective packaging, or molded trays, we supply and configure complete EPS production lines that are engineered for performance, delivered CIF, and backed by sourcing, freight, and installation support.

Our clients don’t ask, “What machine do I need?”

They ask, “How do I produce 18 blocks/hour?”

Or: “How many fish boxes can I mold per day?”

Or: “Can I recycle trim waste into usable EPS again?”

That’s what we solve.

We know the difference between just selling equipment and building a reliable production facility — one that works in Africa, MENA, CIS, Türkiye, Eastern Europe, and South America under real conditions.

From the first pre-expansion cycle to the last shape molding shot of the day, we make sure every component in your line delivers.

Table of Contents

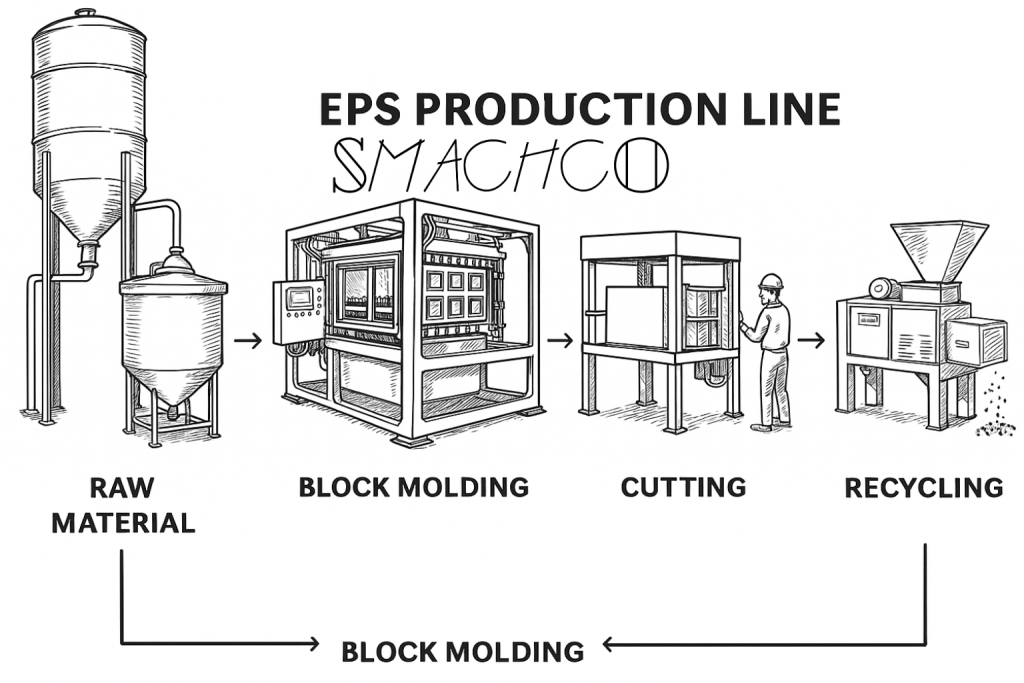

What is an EPS Production Line?

A complete EPS production line includes everything from raw bead expansion to final shape molding or block packaging. A functioning factory typically includes:

- EPS Batch Pre-Expander – for density control (11–35 g/L) with PLC and steam integration

- EPS Silo Storage System – for bead aging and pre-expanded material control (6–12 pcs @ 20–30m³ each)

- EPS Block Molding Machine – full auto, vacuum chamber, hydraulic drive, with size control and recipe presets

- EPS Cutting Machines – hot wire cutting line, vertical + horizontal, adjustable wire spacing

- Shape Molding Machine – hydraulic or pneumatic press for multi-cavity molded foam boxes, trays, protectors

- Steam Boiler + Accumulator – 1.5–2.5 T/h capacity, diesel/natural gas/biomass-fired, with tank and water softener

- Cooling Tower + Pumps – for system-wide temperature control

- Air Compressor System – dry filtered air for shape molding cycles and control valves

- EPS Crusher / Recycling Line – for reprocessing trim, dust, rejected material

- EPS Packing Machine – film wrapper, shrink tunnel, or automated stacking line

- Electrical Control Cabinets – CE-certified, touchscreen, labeled in multiple languages

- Installation & Utility Accessories – piping, valves, pressure regulators, safety controls, etc.

Who We Build EPS Lines For

We supply full EPS systems to:

- 🧱 Insulation panel producers

- 🧊 Fish box and seafood packaging plants

- 📦 E-commerce packaging & foam tray manufacturers

- 🧰 Appliance & industrial protective foam converters

- 🌱 Sustainability-focused factories adding EPS recycling and reuse

- 🏗️ Contractors and private investors localizing EPS capacity in Africa, CIS, MENA, Türkiye, and Latin America

Key EPS Products You Can Manufacture

| EPS Product Type | Use Case / Buyer Type |

|---|---|

| Foam Blocks | Construction, insulation, CNC carving |

| Fish Boxes (with lids) | Cold chain, seafood, fruit packaging |

| EPS Trays & Panels | Meat packaging, bakery transport, pharma |

| Molded Corner Protectors | Electronics, appliances, furniture shipping |

| EPS Decorative Panels | Architecture, branding, events |

| Helmet Padding & Liners | Sportswear, OEM headgear, industrial gear |

| Custom Inserts | E-commerce, equipment shipping, OEM kits |

EPS Plant Capacities We Support

We don’t just ask what machines you want — we ask what you need to produce per day. Then we build around that.

| System Component | Output (Typical) |

|---|---|

| Pre-Expander | 900–1200 kg/h @ 15 g/L |

| EPS Block Molding | Up to 18 blocks/hour (2000×1200×1000mm standard) |

| Shape Molding (Fish Boxes) | 3–6 boxes per cycle × 20–25 cycles/hour |

| Cutting Line | 1 block/min, 20–60 wires, vertical + horizontal |

| Steam Boiler | 2T/h with 8–10 m³ accumulator |

| Recycling Line | 200–500 kg/h reprocessing into usable bead |

Layout Planning & Utility Support

We provide layout planning based on:

- Factory footprint (min. 400–600 m² recommended, 6m height)

- Bead flow logic from expansion → silo → molding or block line

- Utility zones for boiler, compressor, cooling, drainage

- Electrical + piping trenching plans

- Silo layout for gravity feed or pressured discharge

- Stacking, packaging & loading zone flow

You get:

- .DWG + .PDF layout drawings

- Piping specs

- Electrical load table

- Steam balance calculation

- Silo support structure plans

Why Buyers Choose SMACHCO for EPS Production Line

Because we act like your industrial partner, not a machine trader.

With SMACHCO, you get:

- ✅ CIF delivery with full documentation

- ✅ Machines sourced only from verified EPS machinery factories

- ✅ Support in EN / FR / AR / RU / TR

- ✅ Layout planning, civil guidance, and piping diagrams

- ✅ Installation technician dispatch or remote training

- ✅ Integration of block + shape molding into shared systems

- ✅ Spare parts + wear items sourced for 5–10 years

- ✅ Service, not silence, after payment

EPS Production Line Systems We Offer

Here is a sample offer that we can give for one of our EPS Production Line

Standard Block Line Package (2000x1200x1000mm)

- Pre-expander + 8 silos + vacuum block molding

- Cutting + film wrap line

- Boiler, cooling, air system

- Layout + documents + CIF

Shape Molding Line (Fish Boxes / Protectors)

- Pre-expander + 6 silos + molding machine

- 1 mold set (custom available)

- Boiler + air + cooling system

- Packaging or stacking unit (optional)

Hybrid EPS System (Block + Molding)

- Shared silo + steam system

- Separate block + molding output

- Integrated controls

- Ideal for high-productivity, low-overhead factories

Frequently Asked Questions (FAQ)

What’s the minimum plant setup I need?

A basic EPS block or fish box line needs: pre-expander, 6+ silos, 1 molding machine, boiler, cooling tower, and compressor.

What if I only want shape molding (no blocks)?

That’s fine. We can configure a stand-alone molding line with lower utility loads and faster payback.

How long does shipping take?

Production: 30–40 working days (We can always support you for urgency). CIF delivery: 25–35 days depending on destination.

Can you customize molds?

Yes. We can manufacture molds based on CAD or physical samples. Molded box size, cavity count, and wall thickness can all be optimized.

Let’s Design Your EPS Production Line

Here’s what we need to get started:

- Your product type: block, box, tray, packaging?

- Daily capacity goal (e.g. 1000 boxes/day or 12 blocks/hour)

- Preferred fuel type (diesel, gas, biomass)?

- Space available (length × width × height)

- Destination port (for CIF)

- Power supply (V / Hz / Phase)

We’ll send you:

- Layout

- Machine list

- Steam/power load

- Container breakdown

- Technical documents

- Full CIF quotation

Talk to SMACHCO for your EPS Production Line Needs

📧 hello@smachco.com

📞 +90 505 694 21 40

🌍 www.smachco.com

Or in short click here for Contact page!

EPS Production Line doesn’t forgive bad planning.

We make sure your line works.